In an era of rapid technological advancements, the concept of automation has emerged as a pivotal catalyst, reshaping the contours of industries and propelling them into a future defined by efficiency, innovation, and precision.

Automated equipment, at its core, is the technological transcendence that allows for the execution of tasks without human intervention, opening the doors to limitless possibilities and transformative impacts across varied sectors.

One significant contributor to this technological revolution are Automated Guided Vehicles (AGVs), specialized robotic entities designed to elevate industrial processes by performing tasks such as transportation and material handling with remarkable accuracy and reliability.

TecnoFerrari, with its roots deeply embedded in the rich technological soils of Italy, has cultivated a diverse portfolio, specializing in the realms of ceramics, digital printing, logistics, and food processing automation (including meat processing equipment).

The convergence between Gruppo TecnoFerrari S.p.A and Klever Equipped marks a significant milestone in the journey of automation, creating opportunities of collaborative innovation.

Klever Equipped, renowned for its technological prowess, commitment to excellence and vast experience in the meat processing industry, complements TecnoFerrari’s vision, weaving together a tapestry of shared values, mutual respect, and a united aspiration to elevate the landscape of automation technology.

This symbiotic relationship allows customers to embark on a journey to explore uncharted territories of innovation for their industries, unlock new dimensions of efficiency for their companies and to pave the way for a future where technology and human ingenuity coexist and achieve a range of benefits.

In this exploration, we will delve into the transformative world of automation and AGVs & unravel the multi-faceted automation expertise that TecnoFerrari brings to the table.

By embracing the pioneering solutions offered by TecnoFerrari, repetitive tasks can be minimized and skilled workers can be moved to positions of process management, rather than the manual processing usually seen today.

The solutions offered by automation are in demand in all fields and for all companies hoping to compete in the 21st century, from chemical industries to the meat processing sector and food processing plants. The solutions on offer here should showcase just how much efficiency and cost savings can be achieved by any organization willing to embrace automation.

The Automation Evolution

The journey of automation is a compelling narrative of innovation and refinement, a continual process that has seen the transformation of industries and the creation of optimized, efficient operational environments.

Understanding the essence of automation and the pivotal role of Automated Guided Vehicles (AGVs) in this journey is crucial to appreciate the significant strides made in various industrial sectors.

What is Automation?

Automation refers to the application of technology, programs, robotics, or processes aimed at performing tasks that would typically require human intervention.

It is the technological response to the need for increased efficiency, accuracy, and scalability within industrial operations.

Automation in industries implies the use of intelligent systems capable of performing tasks without continuous human input, thereby optimizing productivity and reducing the possibility of human errors.

The significance of automation is multifaceted. It not only aids in streamlining operations but also contributes to enhanced productivity, improved quality, and substantial cost savings.

In the context of industrial applications, automation is a crucial element enabling businesses to maintain competitive advantages by accelerating production cycles, enhancing precision in production processes, and reducing operational overheads.

Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are a critical component in the industrial automation landscape. They are mobile robots used in manufacturing plants and warehouses for materials handling and transport.

AGVs are equipped with advanced navigation technologies, allowing them to move through industrial environments autonomously, following predetermined paths, avoiding obstacles, and ensuring the safe and efficient transportation of goods.

AGVs play a crucial role in optimizing industrial operations. They contribute to the reduction of manual labor, mitigate the risk of accidents, and enhance the overall efficiency of material handling and transport processes.

The integration of AGVs within industrial environments signifies a move towards smarter, more flexible production systems, capable of adapting to varied operational needs and demands.

The role of AGVs is not just limited to transport; they are integral parts of comprehensive automation solutions, contributing their improved accuracy to the seamless functioning and optimization of entire production ecosystems.

They represent a synthesis of mobility and intelligence, enabling industries to envision and realize more refined, efficient, and adaptable operational frameworks.

TecnoFerrari’s Multi-Industry Expertise

TecnoFerrari’s proficiency in the automation domain is not confined to a singular field. Instead, it spans across multiple sectors, each one benefiting from unique, tailor-made solutions that the company develops, reflecting a broad spectrum of automation applications.

TecnoFerrari’s approach integrates innovative technology and custom-designed solutions to meet specific industrial needs, pushing the envelope in sectors like ceramics, digital printing, logistics, and food processing (particularly the meat industry).

If you would like to see the diverse applications of industry automation in action, please follow the link to see real-world examples of TecnoFerrari equipment in action!

Custom Tailored Automation Solutions

TecnoFerrari’s strategy in developing automation solutions is deeply rooted in customization. The company focuses on understanding the distinct requirements of each client and constructs solutions that are precisely aligned with their operational needs and objectives.

This client-centric methodology ensures that every automation system delivered is optimal in functionality and efficiency, addressing the unique challenges and demands of each operational environment.

Through meticulous analysis and design, TecnoFerrari integrates advanced technologies and innovative approaches to develop automation solutions that enhance productivity, reduce operational costs, and improve overall efficiency.

These tailor-made solutions allow industries to overcome their specific operational hurdles and achieve their challenging task with a high degree of precision and reliability.

Ceramics and Digital Printing Automation

In the fields of ceramics and digital printing, TecnoFerrari has introduced significant innovations, setting new standards in quality and efficiency.

In ceramics automation, the company incorporates advanced robotic systems and state-of-the-art control technologies to optimize production processes and quality control, resulting in reduced labor costs and improved productivity.

TecnoFerrari’s digital printing solutions have revolutionized the sector, allowing for high-resolution, intricate designs with customization options, and reducing lead times significantly.

The implementation of advanced color management systems ensures accurate reproduction of designs, enabling industries to meet the growing demand for customized, high-quality products.

Diverse Applications

TecnoFerrari’s automation solutions are versatile and adaptable, catering to a wide range of sectors with varied operational needs.

The company’s logistics solutions, for instance, employ advanced vision systems and a variety of Automated Guided Vehicles (AGVs) to optimize supply chain efficiency, provide real-time equipment monitoring, and accurate inventory control.

In food processing, TecnoFerrari develops advanced automated control systems, enhancing production consistency and facility KPIs.

The company offers solutions for automated doors, AGVs for food handling, and automation software to ensure consistent, high-quality results in food production.

Elevating Food Processing with Automation

Automation within the food processing industry is a transformative advancement, shaping the way food is produced, processed, and packaged. This transformation is marked by the introduction of innovative technologies and methodologies, enhancing the overall efficiency and productivity of food processing operations.

Advanced Control Systems

In the realm of food processing, the introduction and implementation of advanced control systems have been instrumental in optimizing production lines and ensuring consistent, high-quality output.

These systems, characterized by their ability to monitor, control, and optimize various processing parameters in real-time, play a pivotal role in the standardization of production processes and the mitigation of operational discrepancies.

Advanced control systems in food processing leverage sophisticated technologies such as sensors, PLCs (Programmable Logic Controllers), and computer-based algorithms to monitor and regulate diverse processing variables including temperature, pressure, and flow rates.

This ensures optimal processing conditions and enhances the accuracy and consistency of the production processes, translating to improved product quality and reduced waste.

The automation of control systems in food processing not only guarantees the uniformity and quality of food products, but also enhances operational efficiency by minimizing manual interventions and reducing downtime.

This is particularly crucial in sectors like meat processing, where the integration of automated meat processing equipment, governed by advanced control systems, has been transformative, enabling precision and efficiency in meat processing.

Impact on Industrial Food Production

The ripple effect of automation in food processing is widespread, reshaping the contours of industrial food production.

Automation, through its multifaceted applications, is enabling industries to meet the escalating demands for food products, while adhering to stringent quality standards and regulatory compliances.

One of the significant impacts of automation is the enhancement of production capacities.

Automated equipment and processes allow for continuous, uninterrupted operations, leading to increased output and improved efficiency.

This is complemented by a reduction in manual errors and the optimization of resource utilization, which collectively contribute to cost savings and increased profitability for food processing companies.

Moreover, automation is fostering innovations in food production methodologies, introducing new possibilities in food processing and packaging.

It is enabling the realization of more complex, intricate processing techniques and the development of novel food products, thus expanding the horizons of the food processing industry.

In this transformative journey, companies like TecnoFerrari, with their specialized solutions in food processing automation, are leading the way, helping industries navigate the complexities of modern food production and embrace the myriad opportunities presented by automation technologies.

Automation companies are at the forefront, driving innovations and setting new benchmarks in industrial food production through their advanced, tailored automation solutions.

Elevating the Meat Industry: Automated Meat Processing Equipment

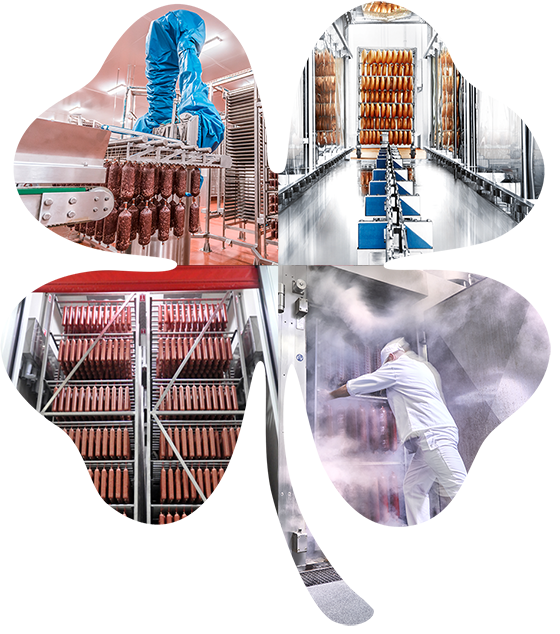

The integration of automated meat processing equipment is likewise revolutionizing the meat industry, marking a significant stride in the realm of food processing automation, by ensuring a high degree of food safety and consistency.

The sophisticated equipment in use today, a culmination of advanced technology and innovative design, facilitates seamless, precise operations, optimizing every aspect of meat processing from slicing to packaging finished product.

TecnoFerrari, with its commitment to innovation and excellence, is at the forefront of implementing these solutions, enabling industries to achieve unprecedented levels of productivity, safety, and quality, ensuring the delivery of premium products to consumers, while also significantly reducing operational costs and enhancing overall efficiency.

Optimizing Logistics through Automation

Automation in logistics is acting as a catalyst for enhanced efficiency and precision in the management and movement of goods. By integrating innovative technologies and automated systems, logistics is undergoing a significant transformation, enabling the streamlining of operations and improved resource management.

Advanced Vision Systems and AGVs

In logistics automation, Advanced Vision Systems combined with Automated Guided Vehicles (AGVs) are pivotal, providing sophisticated solutions to navigate, transport, and manage materials within varied operational environments.

Advanced Vision Systems utilize cutting-edge camera and sensor technologies to enable AGVs to perceive their surroundings (sometimes referred to as ‘machine vision’), navigate accurately, and execute tasks with minimal human intervention.

These systems empower AGVs with the capability to detect and avoid obstacles, follow predetermined paths, and interact intelligently with other systems and humans within the operational environment.

This integration of vision and mobility enables the creation of flexible, adaptable logistics solutions, capable of addressing the diverse needs of modern supply chains and distribution networks.

The deployment of diverse AGVs, each designed to cater to specific material handling needs, such as narrow aisle AGVs and double-pallet AGVs, ensures that logistics operations can be optimized to suit the unique requirements of each facility.

This adaptability and precision, made possible by advanced vision technologies, are crucial in achieving enhanced operational efficiency and reliability in logistics.

Real-Time Monitoring and Inventory Control

Real-time monitoring and inventory control are foundational elements in logistics automation, allowing for precise tracking and management of goods throughout the supply chain.

These systems provide continuous, real-time insights into the status and location of goods, equipment, and vehicles within the logistics chain, enabling accurate inventory management and enhanced operational control.

By implementing real-time monitoring technologies, logistics operators can access instant data on inventory levels, equipment status, and operational performance, allowing for informed decision-making and proactive management of resources.

This level of visibility and control is invaluable in optimizing inventory turnover, reducing holding costs, and minimizing the risk of stock-out (or overstock) situations.

Moreover, the ability to monitor equipment performance and status in real-time enables proactive maintenance and management of logistics equipment, reducing downtime and ensuring the uninterrupted flow of goods within the supply chain.

This contributes to improved operational efficiency, reduced operational costs, and enhanced overall logistics performance.

In this transformative landscape, the integration of automation technologies like real-time monitoring systems, advanced vision systems, and AGVs is proving instrumental in redefining the paradigms of logistics operations, setting new standards in efficiency, accuracy, and operational excellence.

It is this continuous innovation and optimization in logistics automation that are paving the way for more resilient, adaptable, and efficient logistics networks in the future.

Efficiency and Innovation – Two Prerogatives of the TechnoFerrari Supervision Software

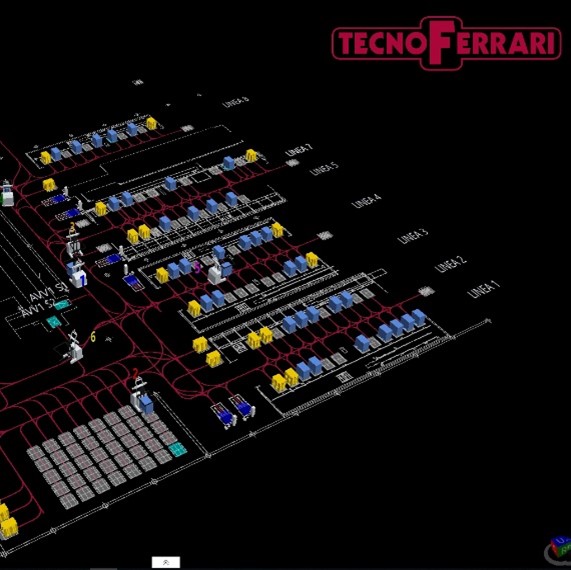

Thanks to its countless years of experience in the automation sector, TecnoFerrari has developed several control and supervision systems for intralogistics plants that can guarantee a complete overview of the production flow.

The innovative software developed entirely in-house, is the result of more than 20 years of experience in the industry, and is designed to be able to develop plants in a simple and fast form, natively integrating the necessary requirements for Industry 4.0.

Main Functionalities of the AGV Supervisor 2D/3D

The main functionality of the 2D/3D Supervisor is to create and manage the missions to be carried out by the AGVs. To do this, the supervisor interfaces in real time with various actors such as the PLCs of the machines (or SQL tables), from this input requests are created to move the material from one location to another location (or zone), a dynamically calculated priority is also associated to the request.

At this point the requests are prioritized, when one of them is executable, the mission is sent to the AGV, via the Traffic Manager, and executed.

Another of the supervisor’s functions is the monitoring of the status of the AGV system. Through the supervisor’s panels it is possible to consult the status of requests, the status of AGVs, the status of communication/signals, the stock and data of the UDCs present, the alarm history, the mission history, and the system error history.

Finally, it is possible to configure and interact with the system: you can put the system in manual or automatic mode, create an anomaly alert, configure vehicle subjugations to zones, cancel missions, send semi-automatic missions, set an AGV charging schedule and their rest positions.

The supervisor is capable of managing fleets of vehicles that differ from each other: routes are dynamically evaluated, the best route is chosen both at the time of its creation and during mission execution. Each flow is studied, developed, and tested by evaluating the traffic loads that arise to provide a ready-to-use solution.

Vehicle missions are updated as the plant situation changes, quickly and transparently. The application and any required changes are simulated in all their parts before installation.

The software is capable of communicating via various protocols with the most widely used field devices in industry. Particular attention has been paid to interfacing with corporate ERPs for the exchange of commands, notifications and moves that normally take place via shared charts. Any non-standard custom interfacing is not excluded in advance and can be implemented to meet the needs of the plant.

In addition, all logs, events and missions generated by system use are made available to the customer via charts or Excel files.

The supervisor continuously monitors battery utilization by assessing the remaining capacity of the entire fleet. Given the workload required by the facility, it autonomously chooses when vehicles need to be recharged, managing turnover at the battery charger so that one or more vehicles are not left without power.

Data from the vehicles are also collected and, cross-referenced with those from the plant, operating, production and utilization statistics are processed, producing a series of KPIs useful for managing and controlling the production and logistics flow.

Data can be filtered by time period or by vehicle, allowing immediate identification of any anomalies. This is a key tool for keeping an eye on the state of optimization, evaluating time trends of various KPIs or the achievement of set goals.

Thanks to the skills of the research and development team, TecnoFerrari is able to offer effective and safe solutions for the movements needed in an innovative and progressive industry.

A Symbiotic Alliance – TecnoFerrari and Klever Equipped

In the dynamic arena of automation, partnerships that amalgamate distinct strengths, values, and expertise are instrumental in driving innovation and excellence.

The understanding between TecnoFerrari and Klever Equipped epitomizes such synergistic collaborations, blending proficiencies and shared visions to pioneer advancements in automation for the benefits of their customers.

Combined Expertise and Values

The collaboration between TecnoFerrari and Klever Equipped is grounded in a mutual aspiration to elevate the standards of automation solutions.

TecnoFerrari, with its multifaceted expertise in automation across various sectors, brings to the table innovative technologies and customized automation solutions.

Klever Equipped, contributing its in-depth knowledge and experience, complements TecnoFerrari’s innovations, enhancing the breadth and depth of the solutions offered.

This union of expertise and values is not merely a confluence of technological proficiencies but is a melding of shared visions and commitments to quality, innovation, and customer satisfaction.

It is this alignment of objectives and values that fuels the development of superior, tailored solutions, addressing the unique needs and challenges of diverse industries, and delivering enhanced value to customers.

Advancements in Automation Integration

Through their combined efforts, TecnoFerrari and Klever Equipped are realizing significant advancements in automation integration.

By leveraging each other’s strengths and insights, they are developing integrated solutions that are more refined, adaptable, and efficient, pushing the boundaries of what is achievable in automation technology.

This collaboration is yielding solutions that are not only technologically advanced but also meticulously designed to ensure optimal alignment with operational needs and objectives.

The integration of advanced control systems, sophisticated vision systems, and innovative AGVs, amongst other technologies, is enabling the creation of holistic automation solutions that optimize every facet of industrial operations.

These advancements are not just enhancing the capabilities of individual automation components, but are facilitating the integration of diverse technologies and systems, enhancing the overall efficiency and effectiveness of automation solutions.

It is this relentless pursuit of excellence and innovation in automation integration that is setting new benchmarks and paving the way for the future of industrial automation.

Explore the Future of Automation Innovation with TecnoFerrari and Klever Equipped!

TecnoFerrari’s groundbreaking automation solutions, in symbiosis with other technical innovations provided by Klever Equipped, are building a future rich with innovation and unparalleled efficiency.

For those eager to delve deeper into this harmonious blend of technology and innovation, explore all we have to offer at the Klever Equipped Booth at Process Expo 2023 (in Chicago this October 23-35) or contact Klever Equipped directly to start taking advantage of their toolbox of automation solutions.

Discover the myriad of possibilities and potential savings that await in this realm of automated brilliance!