With over 70 years of industry experience, Travaglini has established itself as one of the key companies in the field of specialized equipment for high-quality food production. With their expertise in producing equipment for salami and raw ham, Travaglini has answers for all aspects of salting, curing, drying and aging.

Travaglini offers a wide range of equipment which always ensures exceptional results:

- advanced smoking systems

- customized solutions for cheese and fish production

- cleanrooms

- thawing systems

- process automation

- ongoing technical and warranty support

Klever Equipped is pleased to present this expose and to be able to offer Travaglini’s equipment to even more companies in North America this October at Process Expo 2023 in Chicago, providing valuable insights for professionals seeking to enhance their food production processes and overcome modern-day processing challenges.

Leading the Food Processing Industry Since 1950

Travaglini has maintained a leading position in the smoking, fermenting, and drying systems industry since its establishment in 1950. With a focus on high-quality food production, the company has become renowned for its specialized equipment catering to the following industries:

- meat production, particularly raw ham;

- cheese production;

- fish production;

- vegetable production;

- pet food production.

Since its inception, Travaglini has been committed to providing innovative solutions and desirable properties in its’ equipment, that meet the specific needs of its customers and have a wide range of applications. This commitment has allowed the company to establish itself as a leader in the industry, both in Italy and abroad.

Travaglini’s success can be attributed to its continuous efforts in technological development and research. By staying at the forefront of advancements in the meat processing equipment industry, the company has been able to offer a wide range of equipment, that not only meets the requirements of every equipment segment, but also exceeds the expectations of their customers at every turn.

This dedication to innovation has enabled Travaglini to expand its market presence, reaching countries such as countries of the European Union, the United States and Canada, Eastern European countries, Australia and Asia!

As Travaglini enters its third generation of family oversight, the company remains committed to delivering high-quality equipment for the smoking, fermenting, drying processes for the food processing field. With a strong foundation built on decades of experience and considerable growth, Travaglini continues to lead the industry, providing specialized equipment that ensures the production of exceptional food products.

The Art of Curing Meat with Travaglini

The use of cured meat chambers by Travaglini, whether they are larger industrial units, or smaller artisanal operations, has numerous benefits that make it an ideal choice for the curing and aging of meats.

The solutions offered by Travaglini are renowned for their quality and craftsmanship, providing the best solutions to ensure flavorful results. These cured meat chambers are able to perfectly control the thermogravimetric parameters (temperature / relative humidity) in the room, ensuring optimal conditions for curing meats.

Benefits of Using a Meat Curing Chamber in Food Processing

By using proper food processing equipment, like a meat curing chamber or a dry aging cabinet, the process of preserving food is made easier than ever before. These chambers are able to reduce energy consumption by utilizing advanced heat recovery systems, which recycle the heat generated during the curing process.

Additionally, they are designed with safety features to ensure that the cured meats meet all industry standards for food manufacturing. With this technology, businesses are able to produce high-quality preserved products at a much lower cost!

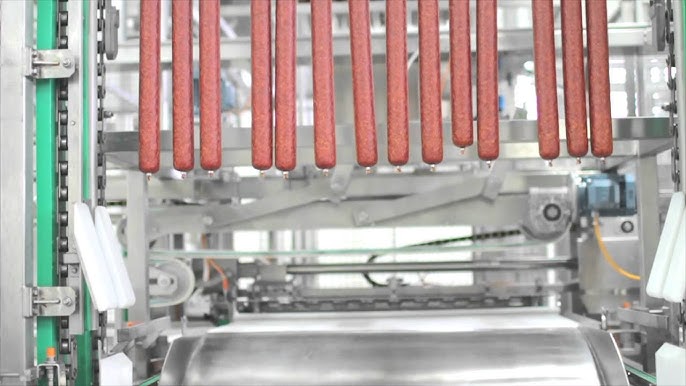

Salami by Travaglini – A Leader in Fermenting

Travaglini is renowned in the cured meat industry for its solutions in the production of high-quality salami. By using leading industry technologies, such as process automation and high trolleys, Travaglini has become one of the staple names in the industry, respected by customers and competitors alike.

Their process begins in a dedicated room where AI controls the temperature and humidity, which has a specific designed HMI (Human Machine Interface) and can be optionally equipped with a natural wood smoker. This provides better fermentation control and uniform shrinkage.

Inside the chamber, the environment is programmed to lower the PH to the desired level, thus providing the most advantageous environment for the starter cultures. After the desired PH levels are achieved, the product starts to be dried with adequate air, temperature and humidity in order to achieve the desired flavor and weight lost, without risking a dry ring (crust formation).

This combination allows for optimal salami production while also reducing health risks associated with poor fermentation control. With these features in mind, it’s no wonder why Travaglini has become such an integral part of the cured meat industry today.

Travaglini is renowned in the cured meat industry for its solutions in the production of high-quality salami. The process begins with a hermetically sealed curing chamber, equipped with a control panel and electric smoker, that provides better fermentation control and uniform shrinkage. Inside the chamber, food dehydrators are used to reduce moisture levels while adequate air movement ensures minimal risk of crust formation. This combination allows for optimal salami production while also reducing health risks associated with poor fermentation control.

The computerized control and management system supplied by Travaglini, in addition to monitoring temperature and relative humidity, allows:

- Setting pre-defined operating programs;

- Control over the fluid temperature, optimizing shrinkage;

- Recording the graphical trending of different variables and displaying on a single screen (temperature, relative humidity, etc.);

- Verifying the exact progression of the entire maturing process.

Furthermore, to allow for various functions to be centrally supervised, Travaglini has designed their software for just this purpose. It allows to monitor and manage system alarms, to collect and graphically displayed the rooms’ individual data, remote programming, remote support, and automatic centralized control for better management of energy consumption.

Raw Ham – The Travaglini Way!

The methodology that Travaglini advocates with its’ equipment for curing ham, requires careful control over temperature and relative humidity levels in order to achieve the desired flavor and food safety. This is not a process for a couple of days!

The process begins in the salting room where hams are soaked for 2 weeks. After that they go into the pre-curing room where they are left for another 2 weeks. Next comes the curing room which can take around 7 weeks, depending on the type of ham being made.

Then comes the drying and washing, taking 1 week to complete. Finally, hams enter the pre-aging room where they are left for 10 weeks, before finally entering the aging room for another 17 weeks. This entire process is designed in such a way so as to maintain temperature and control of humidity at such a level to allow the ham to develop its desired flavor profile. Delicious!

A Look at Smoked Product Solutions

Smoked products are an integral part of the food industry, providing distinctive flavor and texture to any finished product. Travaglini S.p.A.’s expertise in developing smoked and cured meat equipment is unmatched, thanks to their collaboration with leaders in this field as well as their own innovative practices.

The company produces a variety of smoking equipment for producing quality smoked products, such as:

- Cold Smoke Equipment: Equipment that creates a cool environment within the chamber which allows the smoke to penetrate deeper into the meat without cooking it.

- Smoke Room/Smokehouse: A smoke room/smokehouse is used to control the amount of time that each piece of meat spends inside the chamber, resulting in a consistent final product every time.

Travaglini also manufactures other equipment, such as meat drying rooms, making them one of the leading suppliers for all types of smoked meats production needs.

Cheesemaking Equipment

Travaglini specializes in the production of equipment designed for aging and maturing cheese products, using the best industry practices, from specialized stainless-steel rooms, to integrated thermo-hygrometers and even more! The company’s maturing room is designed to guarantee uniform air movement/distribution, correct thermo-hygrometer readings, and controlled gas creation (ammonia and carbon dioxide).

Aging rooms are used for medium length seasoning times of 3-6 months or 6+ months (long) seasoning times. Cheesemaking equipment from Travaglini also maintains temperature and relative humidity ranges, allowing for the development of the product’s characteristic aroma.

Salting, Drying & Smoking of Fish Products

Efficient fish processing solutions are crucial for maintaining the quality of fish products. The food processing industry relies on specialized equipment to ensure that fish is processed in a way that meets the highest standards of quality and consumer safety.

Fish products can be preserved by salting, drying and smoking, using Travaglini equipment to ensure uniform shrinkage (a key component of the drying process), with minimal risk of crust formation and less air pollution for the manufacturing facility.

These advantages make it easier to produce high-quality dried, smoked and salted fish products for consumers who desire freedom from artificial preservatives. In addition, these techniques can help increase shelf-life and flavor of the finished fish products.

Specialized Equipment for Perfect Cold-Smoked Fish

In the context of specialized solutions for high-quality food production, the installation and use of equipment by Travaglini plays a crucial role in all salting, smoking, and thawing processes. The cold smoke technique, as an example, achieved by controlling the ambient temperature, is particularly significant in the production of smoked salmon.

Smoke machines are employed to generate smoke that is cooled before entering the smoking chamber. This ensures that the smoke maintains a low temperature, preventing the heat from altering the texture and flavor of the product.

Additionally, the smoking equipment used must be designed to facilitate the consistent and controlled distribution of smoke throughout the chamber, ensuring that the smoked salmon is evenly flavored. By employing these specialized tools and techniques, producers can achieve consistent and high-quality smoked salmon, meeting the demands of modern-day consumers.

Travaglini Thawing Systems

Travaglini’s thawing system solutions offer a superior alternative to traditional immersion thawing systems. Specifically controlled by air and steam regulation to allow a high-quality defrosting, without loosing proteins in the meat and avoiding bacteria growth on surfaces by controlling the room with the delta of a core and surface probe.

This ensures none of the disadvantages associated with other methods – such as excessive use of water and waste water draining issues. The thawing room monitors for consistent temperature using 2 temperature controller probes.

All of this is done in a controlled environment that preserves flavor, texture, color, and hygiene standards while providing an efficient way to thaw large quantities of meat or fish products quickly. Consumers can rest assured knowing that they are getting quality product from Travaglini’s thawing system solutions.

How Travaglini Clean Rooms Stand Apart from the Competition

Clean rooms supplied by Travaglini are designed to provide superior air quality, temperature and contamination control, ensuring the highest level of food safety for companies.

The company’s cleanrooms are equipped with features that make them stand out from the competition, such as precision room temperature control. Cleanroom temperatures are kept at a constant level and monitored closely to ensure it does not rise above the ambient temperature, protecting against any risk of product spoilage, exceeding humidity parameters or mold growth.

These features make Travaglini cleanrooms ideal for those seeking superior contamination control in order to protect their products from damage, spoilage, and loss of value.

Features and Benefits of Travaglini’s Equipment

Travaglini equipment has many features and benefits worth mentioning. From their cutting-edge monitoring systems, to ensuring exact temperature and ambient humidity in their dry-curing chambers, the equipment always has the needed functionality.

The systems and solutions Travaglini supplies ensure quality control by constantly monitoring the production process and making adjustments as needed. Their equipment also includes energy-saving measures, allowing for more sustainable operations that reduce energy consumption and lower environmental impact.

Travaglini’s specialized equipment ensures consistent product shrinkage that enhances the overall quality of the final product.

Cutting-Edge Monitoring System Ensures Quality Control

The system is designed to monitor various aspects of the production process, including the ambient temperature within the facility, the performance of food processing machinery, and the efficiency of the heat recovery system. By continuously monitoring these parameters, any deviations or abnormalities can be quickly detected and addressed, ensuring that the quality of the food products remains consistent.

Additionally, the monitoring system includes advanced features, such as cooling controls. By incorporating this advanced monitoring system in the equipment they supply, Travaglini can guarantee the production of high-quality food products while providing its customers with the freedom to enjoy safe and delicious food.

Energy-Saving Measures for Sustainable Operations

There are a number of energy-saving measures that Travaglini offers for more sustainable operations. Heat recovery systems in particular play a crucial role in reducing energy consumption by capturing and reusing waste heat generated during production processes. Similarly, the rest of the mentions on this list will likewise have a positive effect on operating costs:

Heat Recovery

- Travaglini’s heat recovery system allow for the total recovery of condensation heat transferred during the refrigeration cycle. Therefore, when the post-heating demand coincides with the requirement for cold, there is hardly any need to use external heating sources.

- Furthermore, hot water around 40 – 45°C can be produced with a Desuperheater (optionally available), which can be used for other processing systems, or other plant needs.

Enthalpy

- The enthalpy system utilizes the dehumidifying power of outside air for as long as possible. The system offered by Travaglini is based on algorithms that allow to use outside air even when one of the specific values (temperature and relative humidity) seems far from the required values.

Economizer

- In systems with an independent refrigeration unit, there is a sub-cooling system that guarantees a refrigeration capacity that is 15 – 18% greater than the absorbed electrical potential.

High Efficiency Motors (IE2 – IE3)

- These motors increase the system’s total output, reducing electricity consumption.

Inverter

- Frequency regulators, installed on the motor of centrifugal fans and/or compressors, that increase or reduce their RPM in order to improve the efficiency if process and/or loading conditions change.

Direct Coupling Motor/Fan

- This particular technical solution, combined with the use of an inverter, allows for a reduction in the system’s electrical consumption, optimizing its regulation.

Modulation of Cooling and Heating Valves

- These changes aim to improve system performance in relation to the actual needs of the product during the various phases of product maturing.

Consistent Product Shrinkage with Air Distribution Systems

Consistent product shrinkage can be achieved through the use of particular air distribution systems. In food production, maintaining the desired shrinkage of products is crucial for ensuring consistent high-quality food. Air distribution systems play a vital role in this process by providing controlled air circulation throughout the production area.

These systems are designed to deliver uniform air distribution, ensuring consistent product shrinkage across batches. By regulating the temperature and humidity levels, air distribution systems create optimal conditions for product drying and shrinkage.

Travaglini equipment allows food producers to maintain a consistent and standardized shrinkage level (essential for achieving uniform product quality), to minimize the risk of spoilage and improve overall production efficiency.

From Sausages to Dry Meat – Klever Equipped and Travaglini Have the Right Cure for You!

The food processing equipment industry has experienced considerable growth in recent years, driven by the increasing adoption of meat processing and the demand for consistent meat products.

According to statistics, the meat processing equipment market size is expected to continue expanding as more consumers seek high-quality and perfectly portioned meats. A key statistic that highlights the economic growth in this industry is the rise in consumer preference for ready-to-eat food products.

With busy lifestyles and a growing awareness of convenience, grocery stores are offering larger quantities of deli meats and fresh meats that are already processed and prepared. This shift in consumer behavior has led to an increased demand for commercial meat processing equipment.

Machine costs have also become a significant factor in the adoption of meat processing equipment. As technology advances and becomes more accessible, smaller businesses and artisanal producers can now afford state-of-the-art equipment previously reserved for larger enterprises. This accessibility has further contributed to the growth of the meat processing industry.

In addition to economic factors, there is a growing emphasis on sustainability within the industry. The use of efficient temperature-treatment and air-circulation equipment, like those provided by Travaglini and sold by Klever Equipped, can help reduce energy consumption and minimize environmental impact.

By offering tailored solutions for exhaust air purification, filtration, and heat recovery, Klever Equipped ensures that their customers not only achieve optimal product quality but also contribute to a healthier planet. Join us in Chicago at Process Expo 2023 this October to pick our brain on how Travaglini products can be integrated into your current operations, or contact us today!