In the realm of food processing equipment, an air purification system from KMA stands as an energy-efficient solution that effectively addresses environmental pollution. By manufacturing high-end systems that are specifically designed to cleanse exhaust air emanating from processes like drying and roasting, KMA Umwelttechnik GmbH contribute to economical heat distribution and climate protection. These are the very reasons that Klever Equipped has chosen KMA as their air filtration supplier of choice and will soon be presenting all of their innovative industrial air purification solutions at Process Expo 2023!

By ensuring clean air while reducing natural gas consumption through their proprietary, highly-efficient filters that comply with emission limit values (and also offer low operating costs compared to conventional methods), KMA facilitates self-financing opportunities for companies by saving energy costs. Additionally, these filtration systems enable businesses to actively engage in environmental protection and sustainable practices within the food processing industry.

With a diverse range of tailored systems available for various applications: in meat, fish and poultry processing facilities, fruit drying plants, herb and spice manufacturing units, as well as nut and cocoa roasteries (and that is only for the food processing industry – view their other air purification solutions here), KMA has successfully installed over 3,000 air filter systems worldwide! From supplying heat exchangers in most European countries, to providing solutions to international giants like BMW and Nestle, KMA will continue to be at the forefront of air filtration innovation.

KMA Air Purification Environmental Impact

The benefits of KMA air purification systems in the food processing industry include: self-financing (due to saved energy costs), prevention of production heat loss, and contribution to climate protection.

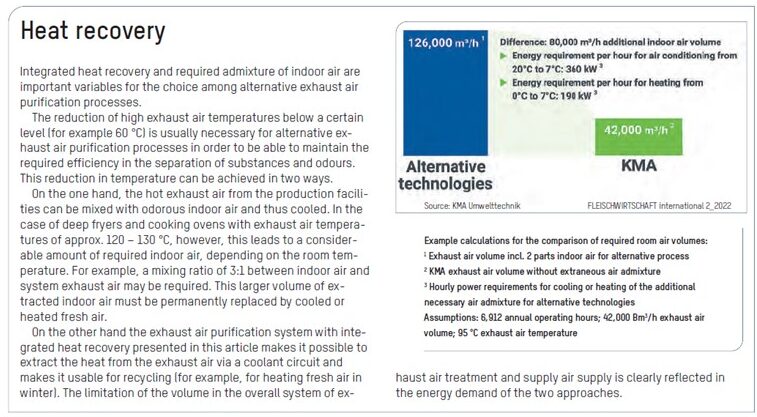

KMA’s industrial air filtration systems provide effective air purification for food processing equipment. KMA air filtration systems are designed to clean exhaust air from drying and roasting processes commonly used in the food processing industry. Additionally, these systems offer odor removal, heat recovery & heat exchanger modules.

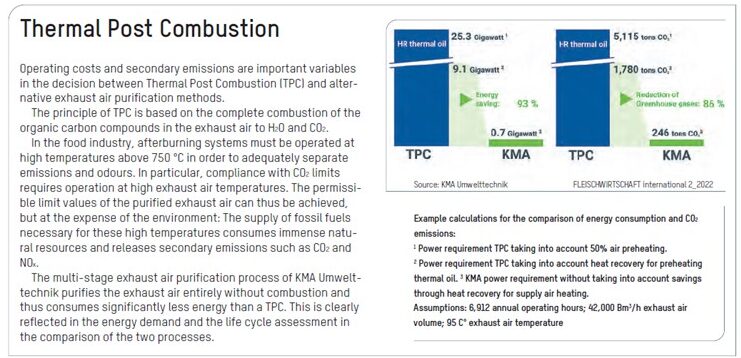

By using KMA air filtration systems, companies can significantly reduce their energy consumption. These systems require about 80% less energy than conventional afterburning systems, leading to substantial cost savings. Furthermore, KMA provides free comparative calculations of operating costs, allowing businesses to make informed decisions about implementing these filters.

In addition to financial benefits, KMA air purification systems play a crucial role in preventing environmental pollution. The efficient removal of pollutants from exhaust air helps maintain clean and healthy surroundings for both workers and the surrounding community. By reducing energy consumption and mitigating pollutant emissions, KMA contribute to climate protection efforts. These filters help lower CO2 levels released into the atmosphere during food production processes.

Overall, incorporating KMA air purification systems into the food processing industry brings tangible advantages such as self-financing through energy cost savings while simultaneously protecting the environment and contributing to climate preservation.

Energy Efficiency at Its’ Finest

One important aspect to consider when evaluating the environmental impact of air filtration systems is their energy efficiency. KMA air purification systems systems offer several benefits in terms of their energy-saving capabilities and environmental impact:

Reduced Energy Consumption

- KMA systems require significantly less energy compared to conventional afterburning systems, with potential savings of up to 80% in energy costs. This reduction in energy consumption contributes to overall energy conservation and helps protect the climate, as well as significant savings in operating costs.

Effective Air Purification

- KMA air purification systems effectively clean the exhaust air from various food processing equipment such as industrial frying machines, smokehouses, drying systems, and roasting plants. These filters ensure high filtration efficiency by complying with emission limit values and various environmental safety regulations and standards.

Environmental Protection

- By replacing afterburning system with a KMA system, industrial facilities can prevent environmental pollution and reduce their CO2 emissions. The innovative design of KMA addresses pollution control problems commonly encountered in the food processing industry, such as smoke and odor emissions.

KMA air purification systems offer an eco-friendly solution for every aspect of the food processing industry by combining energy efficiency with effective air purification techniques. These systems help minimize environmental impact while ensuring compliance with regulatory standards for cleaner production processes.

Advantages of KMA Systems in Different Food Processing Industries

The systems and solutions offered by KMA present many advantages for different food processing applications. Specifically, we will explore their applications for smokehouse use, for frying and cooking applications, for spray drying, food drying, and roasting. Each of these key food processing industries will be discussed objectively and analytically to highlight the distinct benefits of using KMA in these, and other industrial food processing set-ups.

KMA Systems in Smokehouses

Smokehouses in the food processing industry face challenges related to the emission of strong odors and fumes, which can cause problems for nearby residential areas and necessitate environmental protection measures. To address these challenges, filtration systems are essential in smokehouse operations. The following list provides the step-by-step process of how smokehouse filtration works:

- Filtration systems capture and remove odorous substances emitted during the smoking process, preventing them from spreading to neighboring areas.

- These systems use various filter elements, such as electrostatic particles filters and waste air scrubbers, to effectively separate aerosol particles (liquid droplets) and eliminate odor.

- The filtration process ensures that only clean air is released into the environment, reducing pollution and maintaining a pleasant atmosphere.

The KMA Quality Effect on Frying and Cooking

Filtration systems have a significant role in maintaining clean air quality during frying and cooking processes. Industrial air filtration systems are essential for removing particulate matter, odors, and harmful emissions generated during these production processes. These systems ensure that the surrounding environment remains free from pollutants and that workers are not exposed to hazardous substances.

The use of efficient filtration systems in cooking facilities helps control the release of smoke, grease, and other byproducts into the atmosphere. By incorporating advanced technologies such as electrostatic precipitators and activated carbon filters, industrial air filtration systems effectively capture and remove contaminants from the exhaust air. This ensures not only compliance with emission regulations, but also promotes a healthy work environment. Implementing reliable filtration solutions in frying and cooking processes is crucial for achieving optimal air quality control and protecting both human health and the environment.

KMA Filters in Spray Drying

Spray drying is a process used in the food processing industry to convert liquid or semi-liquid materials into dry powders.

- KMA filters provide efficient and effective removal of particulate matter and odors generated during spray drying operations. These filters ensure that the exhaust air released from industrial food processing machines is clean and free from contaminants.

- Many food processing equipment manufacturers already rely on KMA to maintain high air quality standards in their facilities. The filters effectively capture and separate aerosol particles, preventing them from being released into the environment.

- By incorporating KMA into their drying equipment processes, companies can minimize environmental pollution and comply with emission regulations. The use of these filters also contributes to energy conservation and cost savings, as they require less energy compared to conventional afterburning systems.

- Another important aspect to consider is hygienic product recovery. KMA has a customer who produces protein powder who saves a sizeable amount of operating costs every week thanks to the product recovery of the KMA system applied to his spray dryer. Another customer opted for KMA systems is their new production sites rather than using the existing systems recovered product.

KMA Filters in Food Drying

Food drying is a common process in various sectors that involves the removal of moisture from food products to enhance their shelf life and preserve their quality and/or nutritional value. Industrial processing equipment and food processing machinery play a crucial role in this process by providing efficient and effective means of drying. One key aspect of food drying is the utilization of heat recovery systems, which help optimize energy consumption and reduce costs.

To emphasize the importance of industrial processing equipment, food processing machinery, and heat recovery systems in food drying, the following table highlights their key features:

| Key Features | Industrial Processing Equipment | Food Processing Machinery | Heat Recovery Systems |

| Efficiency | Ensures efficient drying process | Facilitates precise control | Optimizes energy consumption |

| Versatility | Suitable for various types of foods | Accommodates different processes | Recovers heat effectively |

| Cost-effectiveness | Minimizes operating costs | Reduces maintenance requirements | Saves energy |

KMA Filters in Roasting

Roasting in the food industry is a commonplace process that involves the application of heat to enhance the flavor, texture, and aroma of various food products. This process is particularly prevalent in industrial smokehouses, where meats and other food items are roasted to achieve desired characteristics. The use of KMA filters in roasting facilities provides several inherent benefits:

Enhanced Control

- KMA Filters allow for precise control over smoke and odors generated during the roasting process, ensuring that these emissions do not cause problems for neighboring areas or violate environmental regulations.

Energy Efficiency

- Through the incorporation of integrated heat recovery in their ventilation systems, KMA Filters enable the recovery of valuable heat from spent exhaust air. This reduces energy consumption and heating costs in production facilities, and contributes heavily to cost savings.

Environmentally Friendly

- By effectively capturing particulate matter and removing odors, KMA filters help prevent environmental pollution associated with roasting processes. They also contribute to reducing carbon dioxide emissions, making them an environmentally friendly choice for the food processing industry.

KMA Systems in Baking Lines

Most production facilities baking lines’ can benefit from the implementation of KMA air filtration systems, which provide enhanced control over emissions and contribute to energy efficiency and environmental protection. These systems are suitable for use in the baking industry, specifically in the context of industrial ovens and other bakery equipment. KMA filters ensure high filtration efficiency, effectively removing particulate matter, odors, and gases from the exhaust air generated during baking processes.

By utilizing these filters, production facilities can comply with emission limit values and safety regulations while maintaining a clean working environment. Additionally, KMA offers low operating costs compared to conventional waste air purification methods. This combination of benefits makes them a valuable solution for controlling emissions and ensuring sustainable operations for baking facilities worldwide.

Purification of the Food Industry

The use of exhaust air purification technology by KMA has been widely recognized and implemented in many food processing applications, showcasing their effectiveness and contribution to environmental protection.

- KMA ensures efficient extraction and control of smoke and odors generated during food processing. This allows for precise regulation of airflow, ensuring optimal filtration performance.

- These systems incorporate heat exchangers that capture waste heat from the exhaust air. This recovered heat can then be utilized for other processes within the production facility, reducing energy consumption and increasing overall efficiency.

- Exhaust air filtration systems by KMA effectively capture and remove smoke generated by smoke generators used in food processing. Through the use of electrostatic precipitation technology and activated lignite filters, these systems efficiently separate aerosol particles, eliminate odors, and ensure clean air is released into the environment.

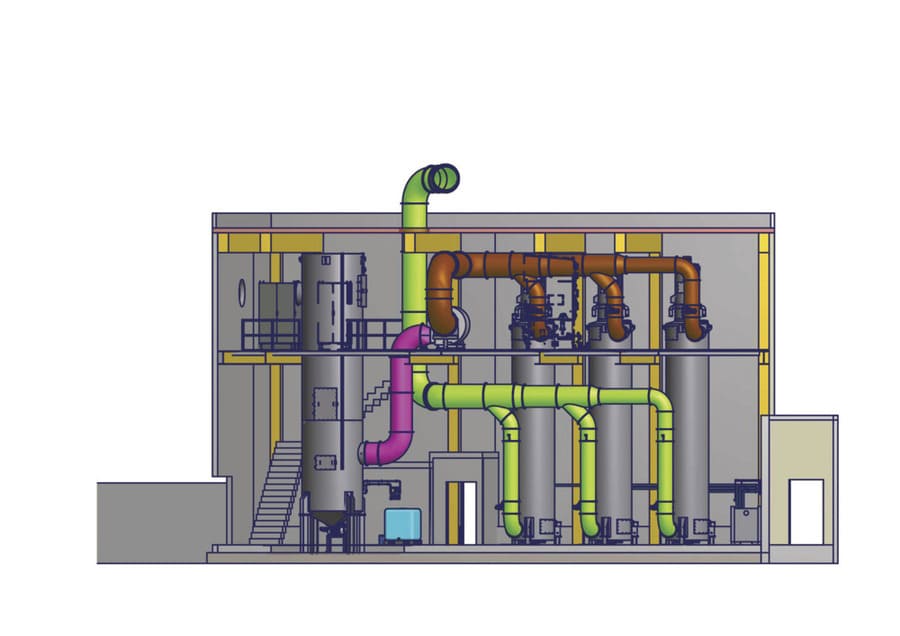

The Solution: KMA Exhaust Air Purification Systems

An effective solution for controlling smoke, odor, and emissions in various production processes is the implementation of exhaust air purification systems. These systems play a crucial role in ensuring industrial air purification and maintaining the environmental standards set by regulatory bodies. In the food processing industry, where smokehouses and other food processing equipment are often located in residential or central city areas, controlling pollution is of utmost importance.

Food processing equipment manufacturers offer exhaust air purification systems specifically designed to address the pollution control challenges faced by the industry. These systems effectively extract particulate matter like grease and tar from the exhaust air while also removing odors. KMA air filtration systems utilize innovative technologies such as electrostatic precipitation and waste air scrubbing to achieve high filtration efficiency.

Implementing these exhaust air filtration systems not only helps prevent environmental pollution, but also leads to significant cost savings for food processing companies of all sizes. By reducing energy consumption and minimizing operating costs associated with conventional afterburning techniques, these filtration systems provide an eco-friendly and economical solution for industrial smokehouses, and many other food processing companies besides.

By incorporating KMA exhaust air purification systems into food processing, facilities ensure compliance with the reduction of emissions and contribute towards sustainable production practices in the industry.

Our Company Vote? It Should be KMA!

KMA are revolutionizing the food processing industry by providing sustainable and cost-effective solutions for air purification. From implementing environmentally-friendly technology, to energy efficient exhaust air purification systems, KMA has all your needs met! Their advanced filtration systems not only ensure high efficiency, but also contribute to environmental protection by reducing carbon emissions. With modules for heat recovery and odor removal, KMA enhances their eco-friendliness and overall effectiveness.

Widely recognized for their quality and innovation, these systems from KMA can be seamlessly integrated into existing production plants without compromising design or food product quality. KMA offer game-changing technology that benefits both the industry and the environment. Klever Equipped will be showcasing all of the solutions mentioned in this article and much more at the upcoming Process Expo 2023 in Chicago. See you there!