Fessmann GmbH, a stalwart master in the realm of food processing, boasts over a century of expertise. As one of the market leaders, Fessmann harmonizes technology and taste in a comprehensive range of smoking, cooking, baking, roasting, and cooling systems.

With a global presence trusted by food processing companies worldwide, they have earned acclaim for ingenious solutions that consistently deliver exceptional flavor and quality. This article delves into Fessmann’s rich history, product innovations, and contributions to sustainable processing practices.

The Beginning of the Fessmann Era

Throughout its history, Fessmann has demonstrated a vision for developing innovative food processing technologies that enhance flavor, extend shelf life, and meet diverse client needs. This vision has been realized through a century of experience in the field of food processing.

From their early developments in smoking systems to their recent advancements in digitalization and sustainability, Fessmann’s vision has continuously evolved to meet the changing needs of their customers worldwide.

Fessmann’s Vision Through the Years

Throughout the history, Fessmann has consistently demonstrated a vision for developing innovative food processing technologies that enhance flavor, extend shelf life, and meet the diverse needs of their clients. This vision has been realized through a century of experience in the field of food processing.

The company’s commitment to excellence shows in several key areas:

Innovation

- Fessmann continually pushes the boundaries of food processing technology, introducing groundbreaking solutions such as digitization of machines, exhaust gas cleaning systems, and process monitoring software.

Quality

- Next to the list, the high-quality systems are designed to deliver exceptional taste and consistent results across all products.

Global Reach

- With a wide customer base and extensive market presence, these systems are used globally and supported by international delivery services.

Customer Support

- Fessmann offers dedicated customer support through a knowledgeable in-house team and distribution partners available for any questions or assistance.

Digitization, Automation and Sustainability in Production by Fessmann

Now, let’s focus on recent developments in the food processing industry, specifically in digitization, sustainable production standards, automation, and efficiency. Understanding these key points is crucial for grasping current trends and advancements in food production processes.

Fessmann and Digitization

The introduction of digitization in FESSMANN’s machines has increased transparency and safety in the production process. This technological advancement has revolutionized food processing by incorporating digital capabilities into food machines and processing machinery.

This integration not only enhances transparency but also improves overall efficiency and productivity in the industry. Key features include:

Real-time Monitoring

- Continuous monitoring of the food processing operation provides live data on parameters such as temperature, humidity, and airflow.

Data Analytics

- By collecting and analyzing data from the production process, digitization enables the identification of patterns and trends that can optimize efficiency and quality control.

Traceability

- Digital systems facilitate accurate tracking and tracing of ingredients, processes, and products throughout the production cycle, enhancing transparency and ensuring compliance with regulatory standards.

Remote Control

- Operators can remotely monitor and control food machines, enhancing operational flexibility and safety.

Fessmann and Sustainable Production Standards

Within the food processing industry, the significance of sustainable production standards has surged. Fessmann, acknowledging this trend, has implemented measures to harmonize its operations with sustainable practices. A notable endeavor is the launch of the exhaust gas cleaning system ECO.CLEANAiR in 2021, heralding a new era in sustainable exhaust air purification.

Additionally, they have implemented heat recovery ventilation systems and waste heat recovery technologies to minimize energy consumption and reduce environmental impact. These efforts not only contribute to resource conservation but also help improve overall operational efficiency.

Furthermore, the company’s commitment to eco-friendly practices extends to its smoking processes as well. The company offers “eco smoke,” a solution that reduces energy consumption while maintaining high-quality results. By adopting these sustainable production standards, Fessmann demonstrates its dedication to responsible manufacturing in the field of food processing.

Automation and Efficiency

Automation and efficiency have become crucial factors in the food processing industry, with manufacturers continuously striving to enhance productivity and streamline operations. Klever Equipped has achieved amazing results for its’ customers by sourcing products from Fessmann, to deliver truly individualized solutions for their customers.

The adoption of automation technologies allows for faster and more accurate food processing, leading to increased output and reduced labor costs.

Industry Automation

- Automated production systems, such as robotic arms and conveyor belts, enable seamless integration of various stages in the food processing line. This reduces manual handling and minimizes human error.

Advanced Equipment

- Advanced machinery equipped with sensors, control systems, and data analytics capabilities optimize process parameters like temperature, humidity, and cooking times. This ensures consistent quality and safety standards.

Streamlined Operations

- Automation enables real-time monitoring of production processes, allowing timely adjustments to optimize efficiency. It also facilitates inventory management by tracking raw materials usage and reducing waste.

Enhanced Productivity

- By automating repetitive tasks, employees can focus on higher-value activities like product development or quality control inspections. This leads to improved overall productivity levels within the organization.

A Global Presence Trusted by Food Processing Companies

Fessmann, as a leading manufacturer of systems for smoking, industrial baking systems and smoke generators, has gained international recognition for its high-tech solutions in smoking, cooking, roasting, baking, and cooling.

With a global reach and extensive market presence, Fessmann’s innovative systems have been trusted by food processing companies worldwide to deliver exceptional quality and flavors consistently.

Spotlight on Three of Fessmann’s State-of-the-Art Systems

Ti3000 Industrial System

The Ti3000 Industrial System has quickly become machine of choice in the North American market! Its features include:

- More yield when compared to similar-class systems.

- Suitable for various meat, fish and protein products.

- Robust stainless steel construction for durability and long-term use.

- The onboard technology allows for flexibility and amazing air circulation.

Fessmann’s Ti3000 Industrial System is truly a game changer, just review out its’ technical specifications.

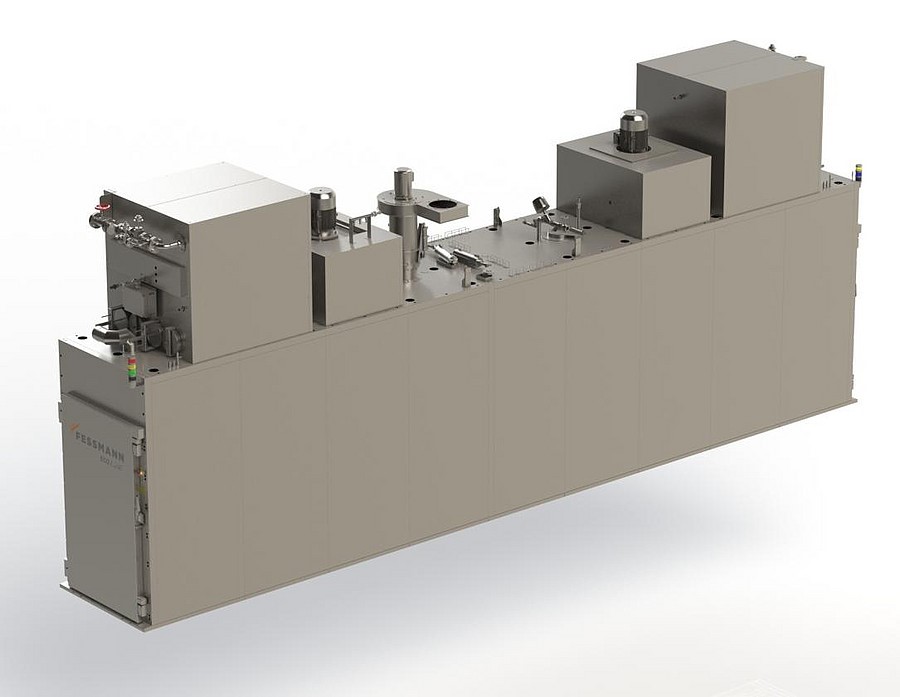

TFi3000 Semi-Continuous System

The TFi3000 Semi-Continuous System offers a unique approach to industrial-scale smoking processes by providing continuous production capabilities. This system is designed for the efficient processing of various meat and fish products, enhancing flavor and extending shelf life. This semi-continuous system is an essential piece of industrial food processing equipment, offering control and efficiency in smokehouse operations.

The TFi3000 Semi-Continuous System provides precise electronic control over the smoking process, ensuring consistent results and meeting the demands of industrial-scale operations. With its advanced features and efficient design, this industrial processing equipment delivers optimal performance and reliability for smokehouse operations.

Ti7000 Universal Smokehouse

The Ti7000 Universal Smokehouse has revolutionized the food processing industry with its versatile system designed for industrial-scale smoking processes. Its features include:

- Enhanced flavor and extended shelf life of smoked products.

- Suitable for various meat, fish and protein products.

- Robust construction for durability and long-term use.

- Eight trolleys for increased productivity, large capacity, efficient airflow system, adjustable temperature and smoking time settings, and easy-to-clean design.

Fessmann’s Ti7000 Universal Smokehouse is truly a game changer in the field of food processing, check out its’ technical specifications for more information.

Fessmann Product Range: Smoking, Cooking, Baking, Roasting, Cooling, Climate & Universal Systems

Fessmanns’ wide range of products includes universal systems designed for versatile applications, as well as specific systems tailored to smoking, cooking, baking, and cooling processes.

Fessmann Universal Systems

Fessmann Universal Systems encompass a wide range of smoking, cooking, baking, roasting, and cooling systems that are utilized by crafts and industrial companies globally. These systems are designed to meet the demands of the food processing industry, providing efficient and reliable solutions for various processes.

Universal Systems Solutions

- Turbomat T1900

- Turbomat T3000

- Ti3000

- Ti7000

- TF3000

- TFi3000

- TF4000

Fessmann Cooking Systems

Fessmann also offers a range of industrial cooking systems that cater to the needs of companies worldwide. These cooking systems are designed to deliver exceptional taste and consistent results across all product types, from meat and sausage, to fungi and snack foods. Fessmann’s cooking systems incorporate advanced smoking equipment, heat recovery systems, and heating recovery ventilators to ensure efficient and sustainable operations.

Cooking Systems Solutions

- Autovent 3000

- TFi3000 Autovent

Fessmann Baking Systems

The baking systems offered by Fessmann incorporate advanced technology and features that ensure efficient and high-quality baking processes. These systems are designed to meet the needs of food processing equipment manufacturers who require precise control over their baking operations.

Fessmann’s baking systems provide reliable performance and deliver excellent results for businesses in the food processing industry seeking precise control over their baking processes while achieving optimum flavors.

Baking Systems Solutions

- RotathermCarat

Fessmann Cooling Systems

Fessmann Cooling Systems s play a vital role in the food processing industry by ensuring efficient cooling and preservation of products. They are designed to meet the demanding requirements of industrial-scale food processing operations. They utilize innovative technologies such as industrial heat recovery, heat exchangers, and air purification to maintain optimal temperature levels and enhance product quality.

Cooling Systems Solutions

- IK3000

- IKi3000

Fessmann Smoking Systems & Generators

Fessmanns’ production of smoking systems and generators play a crucial role in enhancing the flavor and quality of smoked products, be it beef, pork, chicken, turkey, sausage, salami, etc.

These smoking systems are designed to meet the strict demands of today’s food processing industry, providing thought out solutions for achieving the best flavors and results. The high-quality systems offered ensure consistent results across all products, delivering exceptional taste every time.

Their extensive market presence and wide customer base demonstrate the effectiveness and reliability of their products. By incorporating Fessmann’s smoking systems into their production processes, food processing companies can achieve superior flavor profiles in their smoked goods.

Smoke Generators & Smoking Systems Solutions

- RATIO-TOP

- RATIO-FRICTION

- RATIO-LIQUID

- RATIO-HYBRID

Fessmann Climate Systems

Fessmann offers climate control systems – these systems are designed to provide precise control over the temperature and environmental conditions within food processing facilities. These climate control systems incorporate advanced features such as heat recovery units, which allow for efficient energy usage by capturing and recycling heat generated during the production process.

Additionally, ambient temperature sensors ensure that the desired temperature is maintained at all times, leading to consistent results. Furthermore, these climate control systems also include industrial air purification technology, which helps maintain a clean and hygienic environment within the production facility.

Climate Systems Solutions

- CLIMA.LiNE D KNR

- CLIMA.LiNE M KEW

Fessmann Cooking Boilers

The cooking boilers offered by Fessmann are designed to provide precise temperature control and optimize the cooking process in food processing plants. These systems are an integral part of Fessmann’s comprehensive range of food processing equipment.

The cooking boilers are specifically designed for industrial use and can be used in conjunction with other equipment. They offer advanced features and functionalities that allow for efficient and consistent cooking operations, ensuring high-quality results every time.

With their reliable performance and customizable options, Fessmann cooking boilers provide a reliable solution for any business in the food processing industry.

Cooking Boilers Solutions

- NOVA Cooking Boiler

- NOVA Cooling Tank

Product Showcase

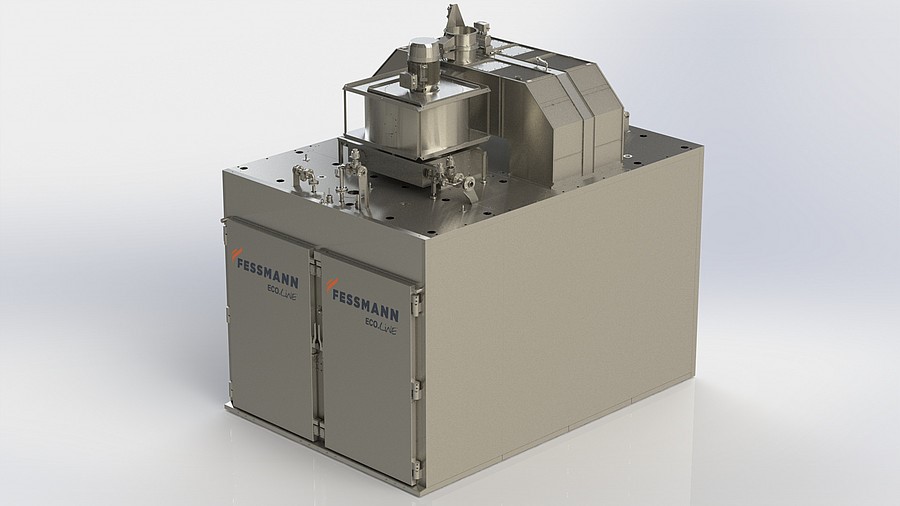

We are pleased to showcase the Fessmann Turbomat T1900.

The Turbomat T1900 is designed for small and medium-sized companies, offering a compact design with minimal space demand while still providing technology and performance comparable to larger models.

Turbomat T1900

The Turbomat T1900 is a compact smoking system designed for small and medium-sized companies. Its compact design optimizes space utilization while providing efficient airflow within the chamber. With precise control over the smoking process, it delivers consistent results and exceptional taste to smoked products.

Advancements in Exhaust Air Cleaning and Control Technology

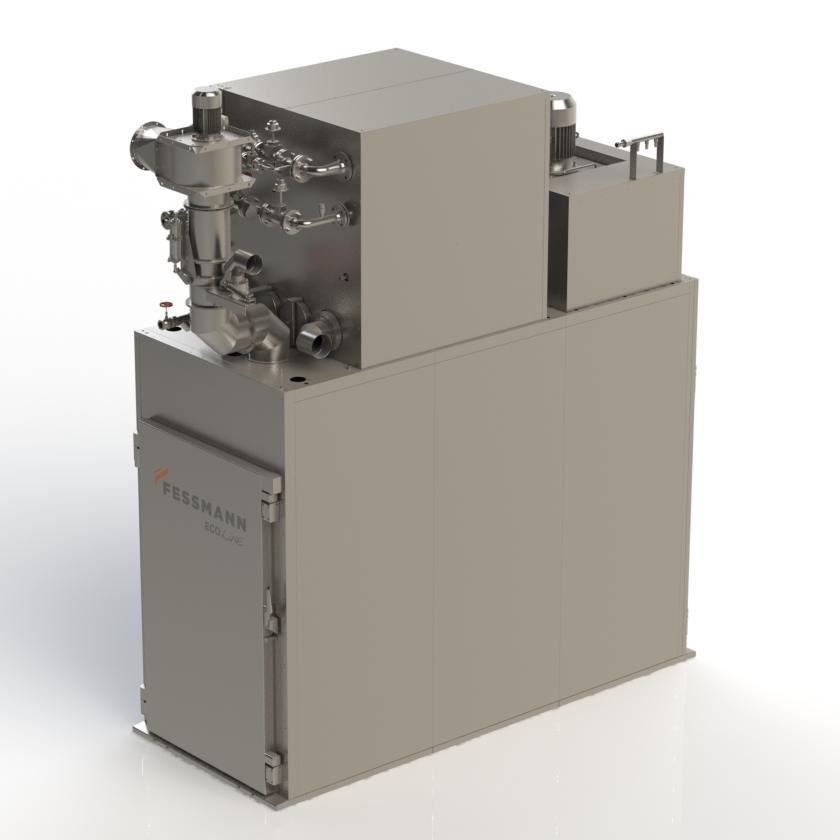

Introduction of the exhaust gas cleaning system ECO.CLEANAiR in 2021 has set new standards for sustainable exhaust air cleaning, showcasing Fessmann’s commitment to innovative advancements in control technology.

This key innovation addresses the crucial need for effective and environmentally-friendly solutions in food processing.

Advanced Exhaust Air Cleaning

- Utilization of advanced technologies removes harmful pollutants and contaminants, ensuring clean and safe air emissions.

Sustainable Solutions

- Fessmann’s commitment to sustainability is evident in the design of the system – by reducing emissions and minimizing environmental impact, this step aligns with global efforts towards a greener and carbon-neutral future.

Enhanced Control

- The ECO.CLEANAiR system incorporates state-of-the-art control technology that enables precise monitoring and adjustment of exhaust air cleaning processes – this ensures optimal performance, efficiency, and compliance with regulatory standards.

Improved Operational Efficiency

- Automated features and intelligent controls streamline operations, reduce manual intervention, and enhance overall productivity in food processing facilities.